Small-Batch Production of Stand-Alone Systems and Individual Components

Basic Laboratory Equipment in Small Batches for Effective Processes

CYBERTRON Berlin is your experienced partner for small series production – from design to manufacturing of the desired machines in small series. The advantage: you are involved in the entire process, from planning and manufacturing of all components and production of the prototype to series production. This ensures that the product and all parts meet your exact requirements.

Trust our expertise: For over 40 years, we have been developing and producing customized automation systems for customers in medical diagnostics, research, and for production. Fast, precise, and at high quality.

What is Small Series Production?

Small series manufacturing or small series production refers to the production of a limited number of identical products, often between 10 and 1,000 units. The production of series with fewer than 10 units is also referred to as small or micro series. Small series can be used to manufacture either stand-alone systems or individual components of these systems.

In laboratory technology, laboratory automation, research, and medical technology, it enables the manufacture of specialized devices or components for specific applications without the costs and effort of mass production or the limitations of single-unit manufacturing. This manufacturing method is ideal for prototypes, research projects, or niche products that require individual customization. It offers flexibility and allows companies to test innovations more quickly and bring them to market. In research and medical technology in particular, customized products are often necessary to test and apply new technologies.

Examples of Small-Batch Products from CYBERTRON

We have already manufactured numerous products and components in small series for our customers. These are suitable for a wide variety of applications. In the field of liquid handling in particular, we often take on the planning and manufacture of small series, e.g. for in vitro diagnostics or sample preparation and provision. Below, we have compiled two examples of our small series production for you:

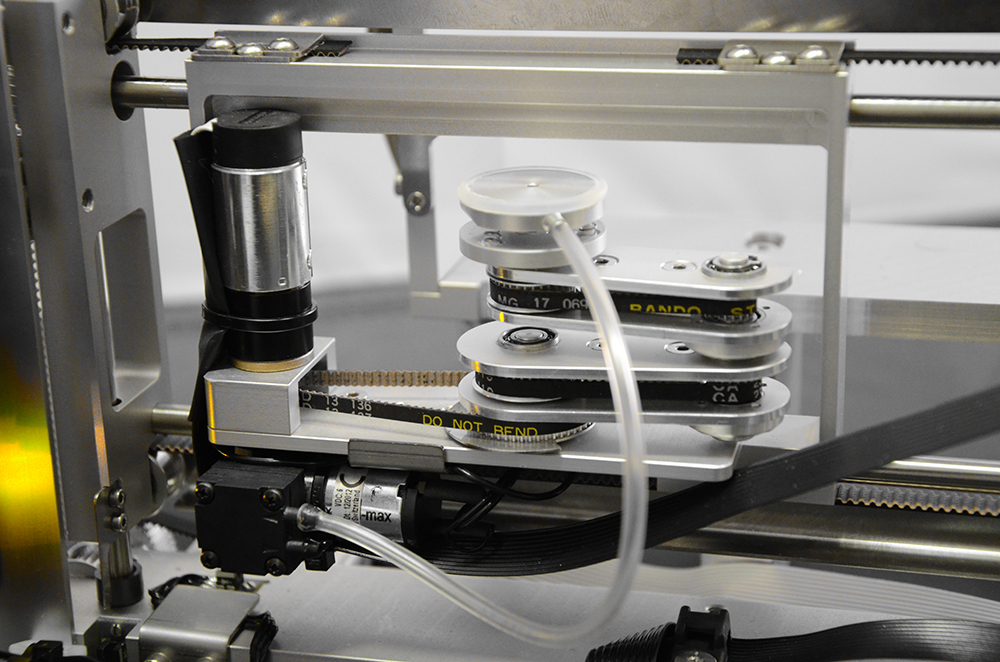

Autosampler

A laboratory equipment supplier commissioned us to undertake the small-batch production of a modular autosampler. Thanks to our many years of experience in developing high-precision automation systems, we were able to ensure that the autosampler precisely met the customer's requirements—from automated sample preparation and active sample cooling to sensor-based temperature monitoring. Our modular implementation allows the autosampler to be flexibly adapted to different laboratory applications, ensuring maximum efficiency in daily laboratory work.

Specifications:

- Insulated and sealed cooling chamber

- Active cooling

- Modular design of the kinematics and cooling unit

- Sensor-based temperature measurement

- Y-drive of a tray

- Accommodation of MTPs on the tray

- Automated tray feed from the front

- XY drive of a dosing needle/piercer

- Extremely compact design

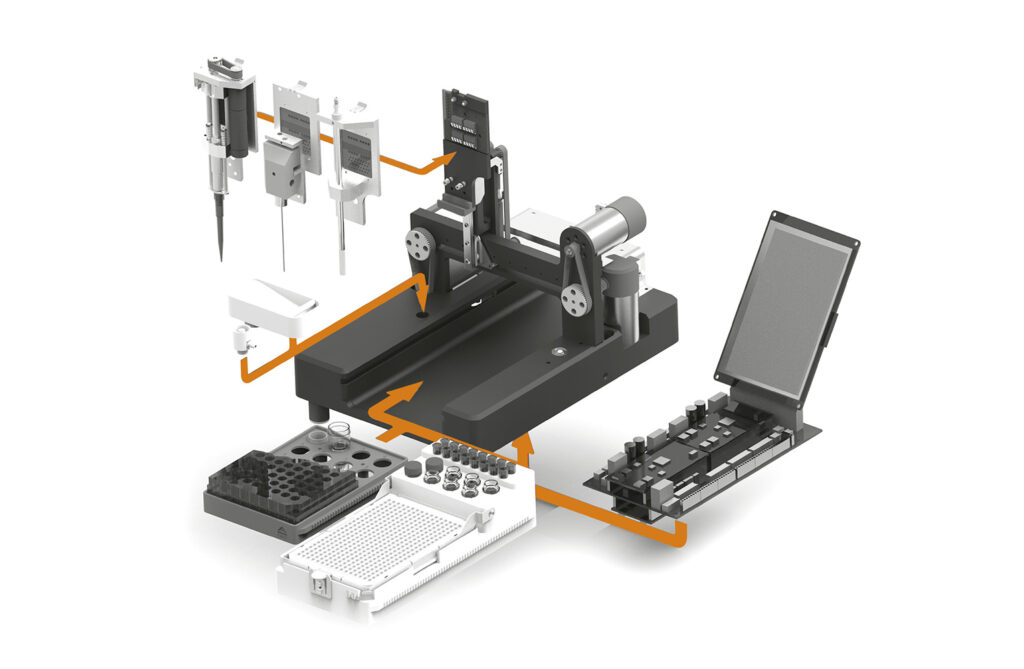

Strip Tester

We took over small-batch production of strip testers for a laboratory technology provider. Thanks to our expertise in manufacturing modular systems, we were able to ensure that each device met the exact requirements of end users in research and diagnostics—from the automation of test procedures to secure sample processing.

Specifications:

- Automated LINE/Dot Immunoblot Analyzer with low space requirements

- User-friendly software

- Simultaneous processing of up to 24 different assays

- Ready-to-use reagents and test strips

- Automatic identification of cartridge and test strip barcodes

- Export of results in PDF or XLS format or as a printout

- Integrated drying of processed test strips

- Evaluation of processed test strips

- LIS connection

- Low maintenance, no fluidics

Other Technologies we can Manufacture in Small Batches

- Pipetting platforms and mini pipetting platforms

- Single and multi-axis systems (linear and rotary)

- Piston stroke pipetting systems (1K - 8K, 10 - 5000µl)

- Needle dosing systems (1K - 20K)

- Liquid level detection (needle + pipette)

- Gripping systems

- Camera systems (simple, neural networks, AI)

- Carrier systems (samples, reagents, glass slides)

Are you Looking for a Small-Batch Manufacturer for your Laboratory Technology?

We are happy to to offer you a consultation. Discuss your requirements and the requirements of your customers with us in detail. We will find the right solution and the ideal quantity for your series.

Your Advantages at a Glance

Why Small Batch?

- Fast market launch: With our innovative solutions and systems in small series, you can respond quickly to growing demands in your industry.

- Flexibility: The devices can be adapted to specific requirements—quickly, easily, and exactly when needed.

- Scalability: It is possible to increase the number of units as needed without costly changes in production.

- Modular design: Our modular systems allow flexible adaptation of devices and components. Each device can be expanded or adapted with manageable effort to meet future requirements – without the need for complete remanufacturing.

- Cost efficiency: Compared to one-off productions, small series are more economical because the production costs per unit are lower. This allows material procurement and production processes to be optimized.

Why Choose CYBERTRON Berlin?

- High degree of customization: We specialize in tailor-made solutions in the field of laboratory automation that are precisely tailored to the needs of our customers.

- Precision and highest quality: With the help of modern 3D printing processes and high-precision milling machines, we can produce even complex individual components with the highest accuracy. This ensures that all components meet the exact requirements. All manufactured parts—e.g., sheet metal parts, bent parts, milled parts, and turned parts—are manufactured in Germany. Using 3D printing, we can also quickly implement numerous customer requests in-house.

- Comprehensive consulting: From planning to implementation, our highly specialized team offers you detailed consulting to develop the most suitable automation solutions.

- Experience and expertise: With years of experience in the development and production of solutions for laboratory automation, we successfully produce high-quality and reliable devices and individual components in small series.

- Technological expertise: Our team has in-depth specialist knowledge and works at the cutting edge of technology. This enables us to integrate reliable and state-of-the-art technologies and implement your systems efficiently and precisely in small series.

Make everyday lab work easier! In addition to small-batch production, we also support you as a special-purpose machine manufacturer, developing and manufacturing customized machines for medical and laboratory technology. If required, we can also develop the necessary electronics or supply high-quality components such as axis systems for a wide range of automation systems.

We make it possible!

Are you facing demanding questions and extraordinary challenges? Do you have an idea for a device or individual component and need support with the technical implementation? Then you've come to the right place. At CYBERTRON Berlin, we welcome unusual or challenging tasks at any time.

Talk to us about your goals and we will develop tailor-made systems for you – as individual devices or in small series production. Take advantage of the expertise of the entire CYBERTRON team and get a strong partner at your side to help you realize your project. We look forward to your inquiry – by phone at 030 830309350 or via our contact form.