Axis Systems and Kinematic Systems

Compact design for precise work

As experienced developers in the field of laboratory automation and special machine construction, we know that three things are important for a good kinematic or axis system: precision, positioning speed, and price.

CYBERTRON Berlin offers a customizable range of linear and rotary axis systems as well as kinematic systems that guarantee maximum precision and efficiency. Thanks to standardized travel ranges, our axis systems are available particularly quickly. Components such as heavy-duty precision spindle axes, linear guides with direct drive, and multi-axis systems enable sophisticated motion sequences. Take advantage of compact designs, high load capacity and dynamics, and cost-optimized performance for your automation and measurement technology applications! Contact us and work with CYBERTRON to find the optimal solution for your specific requirements!

Our Axis Systems at a Glance

The µMove axis system is the smallest in its class and impresses with maximum precision and minimum space requirements. This makes it particularly suitable for demanding positioning tasks in micromechanics and laser technology, where precise movements are required in the smallest of spaces. Its compact design allows for easy integration into existing systems and ensures smooth automation processes.

The pMove axis system is also extremely space-saving and therefore ideal for installation in compact machines and devices. This axis offers an outstanding combination of stability, speed, and precision. Both linear axes can be easily mounted as a cross-axis system, creating flexible and versatile solutions for a wide range of applications. You get maximum flexible movement with our rotary axes, which can also be easily retrofitted using a suitable rotation unit.

Our CLiCK axis systems offer you the highest level of modularity. Thanks to their structured design, you can determine everything from the length to the positioning accuracy. We will of course be happy to advise you and help you with your selection and configuration.

The kinematic systems are suitable for three-dimensional positioning. Discover our highly customizable range and discuss the requirements for your axis system with us. We will be happy to implement your wishes.

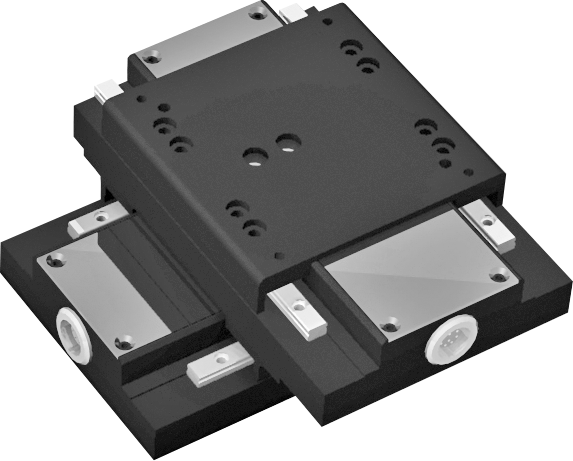

µMove Axis Systems

The µMove axis system impresses with its compact design featuring a short overall length and large stroke, low height, and wide guide spacing, making it ideal for installation in compact devices and machines. All essential components—drive, measuring system, enclosed ball screw, guides, and interface modules—are integrated into the base body, ensuring high stability and precision of the mechanics. In addition, the system is plug-in ready and can be connected directly to a servo motor controller. This makes it perfect for high-precision positioning tasks in micromechanics, laser technology, and for measuring, testing, and assembly applications.

Technical Data:

- 2 variants: wide and narrow carriage

- As linear or cross-axis system

- Speed: max. 25 mm/s

- Repeatability: 8 µm

- Acceleration: max. 10ms-2

- Stroke: 36 mm

- Payload: 1 kg

- Mass: 280 g

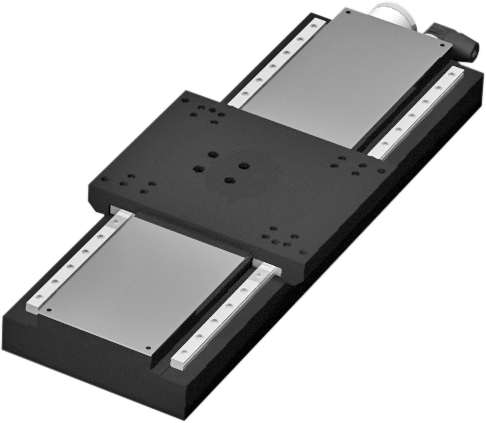

pMove Axis Systems

Similar to the µ-Move axis system, the pMove axis system is characterized by its compact design with a short overall length, large stroke, and wide guide spacing, enabling space-saving integration into machines and devices. All important components are built into the base body, and the integrated electronics reduce the cabling effort to a compact, industrial-grade connector. Thanks to robust recirculating ball guides, the device can withstand high loads. The plug-in system is ready for immediate connection and is ideal for precise and fast positioning tasks in measuring, testing, and sample handling systems.

Technical Data:

- 2 variants: wide and narrow carriage

- As linear or cross-axis system

- Speed: max. 60 mm/s (P1) max. 120 mm/s (P2)

- Repeatability: 8 µm

- Acceleration: max. 20ms-2 (P1) max. 10ms-2 (P2)

- Stroke: 80, 150, 200 mm (standard)

- Payload: 10 kg (P1), 5 kg (P2)

- Weight: 980 g (with 80 mm stroke)

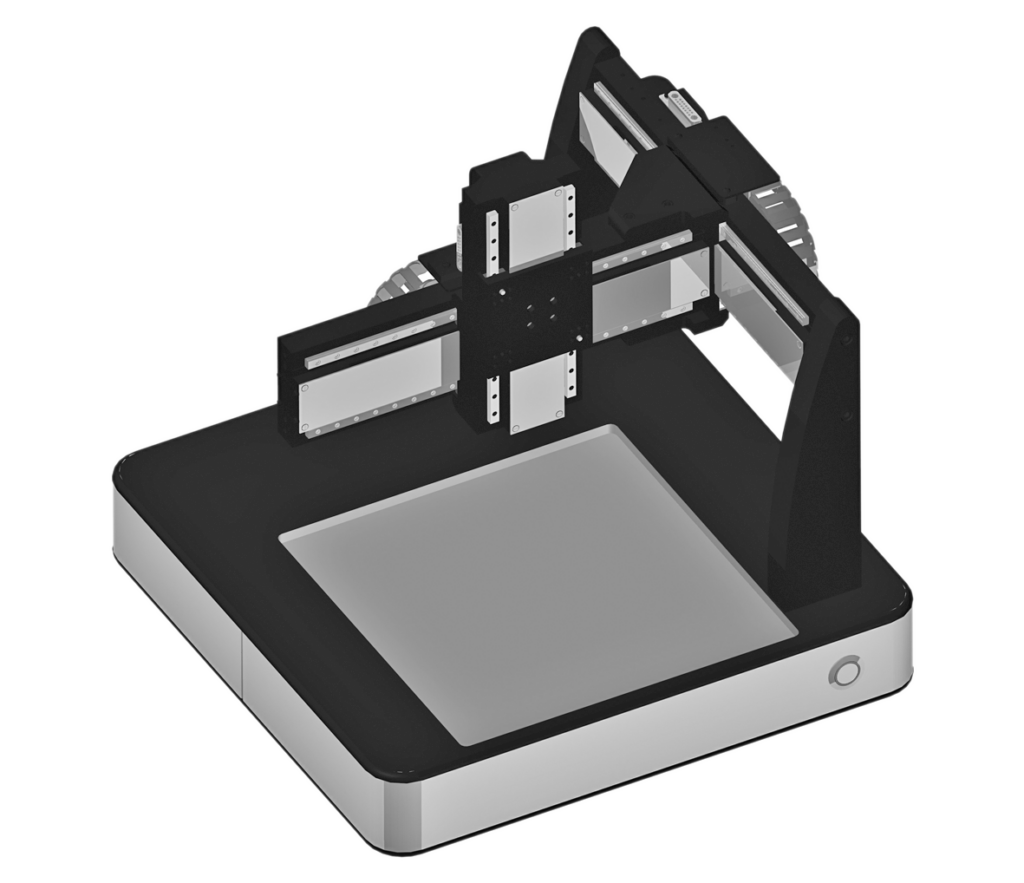

pMove – Xyz Benchtop Kinematics

The kinematic system allows easy access to the work area and straightforward installation of transfer belts, OEM modules, or rotation units. The axes are kept narrow for space-saving integration, while the robust industrial design with a wide-range power supply and powerful 4-axis servo motor control ensures a long service life and high dynamics even under high kinematic loads.

The additional servo motor output and versatile inputs and outputs allow easy control of a wide variety of laboratory peripherals. The movement and speed of the benchtop kinematics can be conveniently controlled via a PC.

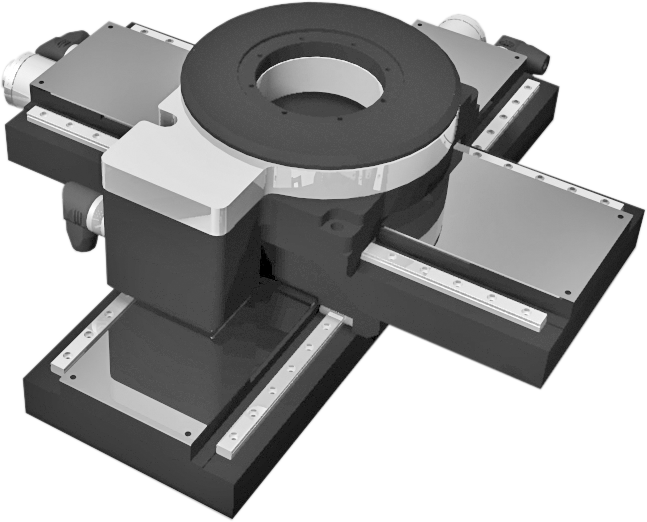

pMovePhi – Rotation Unit

The rotation unit impresses with a >360° rotation that can be performed almost infinitely, as there is no stop installed. With its central 56 mm bore, it fits perfectly on our linear axes and enables a superimposed rotational movement. Thanks to its clear width, it is perfectly suited for optical applications and underfloor lighting.

The compact integration of the servo motor, toothed belt drive, and measuring system in the base body enables maximum precision and stability with minimal space requirements. The compact industrial connector ensures simple, interference-free cabling. This makes the rotation axis system ideal for dynamic, fast rotations under medium loads – a powerful solution for demanding applications.

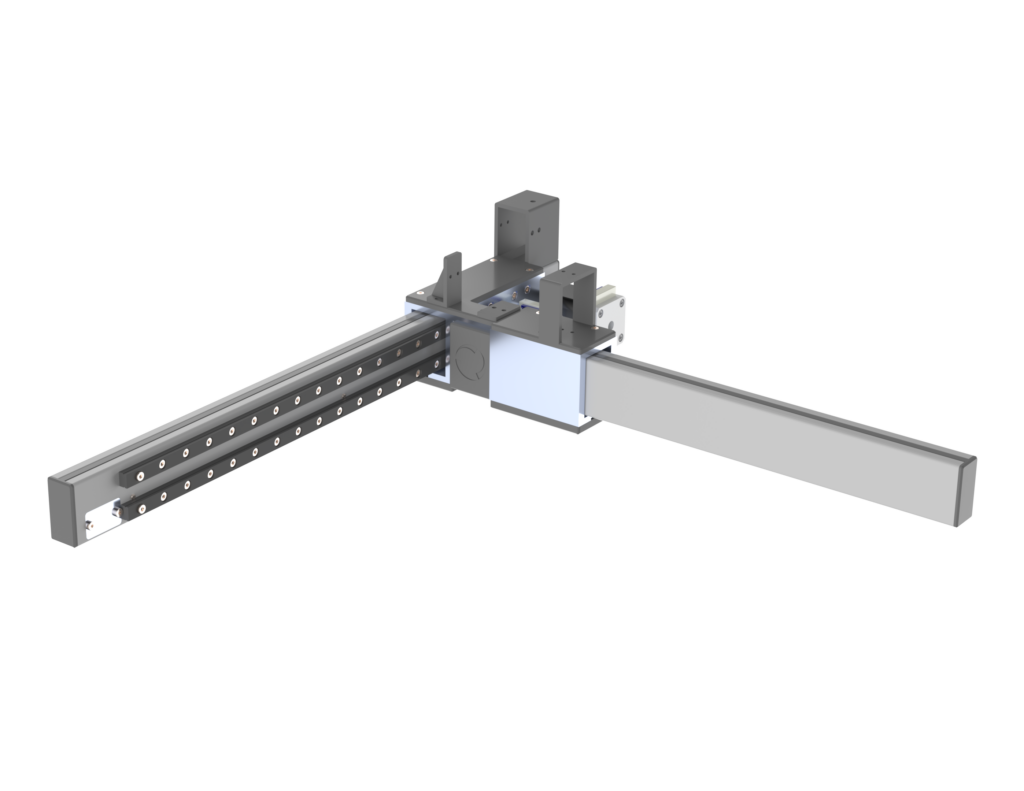

CLiCK – Customizable Linear Cantilever Kinematics

Our highly modifiable axis system offers a solution for every budget. Each axis stands alone and can be equipped with intelligent motors based on our Steppertron stepper motor control. The axes can be combined as desired to upgrade from single to multi-axis systems. When the axes are connected to form a gantry, there are a wide variety of possible combinations. From cantilever systems, as shown here, to variants guided on both sides, which can be implemented either suspended or standing. Determine the number and quality of the guide rails according to your requirements and application. You have a full range of options, from cost-efficient axes for simple tasks to high-end axes for precise positioning at maximum speed. You can upgrade or downgrade your systems at any time with minimal effort. You can also specify the drive types (DC servo motors, stepper motors) to configure your desired system. Do you have questions about the options or would you like to make an inquiry directly? Then please contact us personally with your request.

Additional Components for Even Greater Efficiency

Thanks to the simple operation via our Steppertron, IQ5500, and IQ5500compact device and motor controllers, our axes can be controlled efficiently and optimally adapted to specific requirements. Whether high-precision positioning, fast motion sequences, or reliable integration into automated machines—CYBERTRON axes offer tailor-made solutions for every challenge in modern automation.

CYBERTRON's axis systems and kinematic systems combine speed and accuracy. At the same time, the standardization of our small series enables timely implementation. This means that axis solutions with standard strokes of 30, 80, 150, or 200 millimeters are quickly available for laboratory equipment.

Your Axis System: Precision and Efficiency With Cybertron

Precise positioning, dynamic movement, and long service life at a reasonable price: CYBERTRON offers axis systems and kinematic systems that fit compactly into machines for laboratory automation. With over 40 years of experience, we offer tailor-made solutions that are tailored to the requirements of pharmaceutical companies, medical device and IVD manufacturers, as well as research laboratories and diagnostic centers. Of course, we also offer laboratory equipment for other specializations. In the field of laboratory automation, we offer cost-effective small-batch production—for example, for liquid handling—as well as special machine construction for medical technology and customized electronics development.

In addition to technological excellence, you benefit from customized solutions and our comprehensive support. From concept to implementation, we are happy to assist you in finding the optimal automation solution for the individual requirements of your laboratory. We look forward to your inquiry—by phone or via our contact form.